Remain safety compliant with a reliable Australian test and tag brand.

Request your free quote for test and tag services and find out how to safeguard your workplace from safety issues, and maintain OHS/WHS compliance.

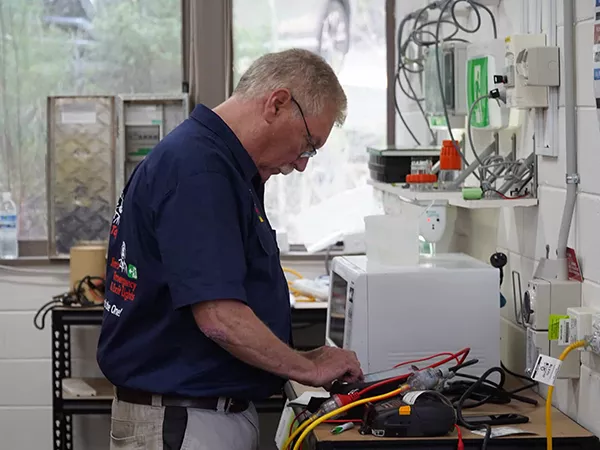

At Jim’s Test & Tag, we can check and test your electrical and fire safety equipment to make sure that its in safe working order and in line with OHS/WHS requirements. With 200+ franchisees across Australia, we have an expertly trained and fully qualified technician near you.

Keep Your Business OH&S Compliant

Want to remain OH&S/WH&S compliant and safeguard your workplace? Jim’s Test & Tag specialises in the testing and maintenance of a range of compliance requirements such as Electrical testing, Fire Equipment testing, Safety Switch (RCD) testing, Emergency Exit Light testing and maintenance and First Aid kit maintenance. We can help to reduce the risk of serious injury to your staff and customers and avoid heavy fines from OH&S/WH&S infringements. Contact us today for a free quote and ensure that your workplace meets the Australian Safety Standards.

Our Services

Reliable Test & Tag Service From A Brand You Can Trust

Keep Up To Date With Our Newsletter

Sign up to our newsletter to receive all our latest offers and expert advice.

Leave your details below and subscribe today!

Become A Franchise Owner

Benefits Of Owning a Jim’s Test & Tag Franchise

What Our Clients Say

The service provided by Vivek was excellent. He called us back within 10 minutes of us making an enquiry and turned up exactly when he said he would. We will definitely use again, can thoroughly recommend.

– Fencemate Limited

I needed to get some new equipment tested and tagged so we could commence a project on a building site. I was struggling to find anyone to do this and Jim’s Test and Tag was suggested.

They helped me out of a predicament and were courteous and efficient, I will use them from now on.

– Secure Storage Systems

Our experience with Tony from Jim’s Test and Tag has been awesome, his communication and service was outstanding. We received a quote within minutes of our initial inquiry and knew exactly what the costs would be. Tony arrived when he said he would and was very professional. We can definitely recommend Jim’s Test and Tag

– MDA Canterbury

Read more reviews at:

Enjoy Freedom And Flexibility By Becoming A Franchise Owner

Tired of working for someone else? Become your own boss with a Jim’s Test & Tag and Fire Safety Franchise. We’ll give you comprehensive training on how to successfully run your own Test & Tag business. You’ll enjoy regular income as well as the flexibility, lifestyle and freedom which comes from owning your own business.

Join us and 5,700+ others who have decided to bring unbeatable service across the world.